What is SECS/GEM?

SECS/GEM is a communication protocol between manufacturing equipment (such as machines that produce CPUs, cell phones, solar panels, flat panel displays) and a Factory Host System. The Factory Host System is responsible for controlling numerous pieces of equipment and extracting data from them. Like any language, SECS/GEM has its own set of rules, defined by SEMI (Semiconductor Equipment and Materials International). The SECSGEM.NET Demo Application is an example of its implementation.

What does SECS/GEM stand for?

Semiconductor Equipment Communication Standard / Generic Equipment Model. SECS and GEM together allow the integration of manufacturing equipment with a Manufacturing Execution System (MES), a crucial software that determines what to produce and when.

What is GEM300?

GEM300 is an advanced extension of GEM, developed when the semiconductor industry transitioned to 300mm wafers. At the same time, SEMI introduced new methods for equipment control, leading to the creation of GEM300. Although the industry has since started using 450mm wafers, GEM300 is still applicable. GEM300 is more complex than the original GEM because it enables the use of Control Jobs and Processing Jobs, instead of relying on simpler GEM commands like PP-SELECT. We are here to provide guidance and assistance with these systems.

What is SECS/GEM used for?

- To remotely control equipment.

- To upload, download, and modify recipes remotely and store golden recipes.

- To monitor equipment status in real-time.

- To collect data from equipment to optimize processes.

- For error reporting, reducing operational downtime.

- For material quality control.

Who uses SECS/GEM?

SEMI Standard SECS/GEM Software allows MES systems (Manufacturing Execution System) to communicate with multiple pieces of equipment using just one language—SECS/GEM. Equipment manufacturers use SECS/GEM to integrate their machines into customers production lines, enabling remote control without human intervention and the transfer of production data (e.g., measurements, equipment status) to the customer’s Host System. SECS/GEM is used in smart factory automation across various industries.- Equipment manufacturers.

- Semiconductor fabrication foundries (both front-end and back-end).

- Surface Mount Technology (SMT) equipment manufacturers.

- The photovoltaic industry (PV2).

- Flat-panel display manufacturers.

- Final assembly test and packing (FATP) producers.

- Packaging markets.

- Materials markets.

- Test equipment manufacturers.

- MES software vendors.

Why should I use SECS/GEM?

- All semiconductor manufacturers and foundries require the use of SECS/GEM.

- SECS/GEM allows the Customer Host System to monitor your equipment’s activity, including what, when, how, and with what it is operating.

- SECS/GEM is a time-proven solution, in use for over 40 years and deployed on hundreds of thousands of pieces of equipment.

- The SECS/GEM connection is stable, using a TCP/IP backend.

- Learning SECS/GEM is moderately difficult, and integrating it with equipment takes 2 to 4 months. Sometimes, rethinking the software architecture is necessary, which could take over a year—but don't worry, we are here to help!

Why should I buy SECS/GEM software instead of developing it in-house?

- Developing a mature SECS/GEM library takes about two years. Implementing GEM300 capabilities adds at least another year. The cost savings from using our easy-to-use, mature, scriptable, and cross-platform SECS/GEM solution would be immense compared to in-house development.

What sets our SECS/GEM software apart?

- We have successfully integrated hundreds of machines for industry leaders such as Intel, Texas Instruments, Micron, and OnSemi. All of this valuable experience has been incorporated into the SECSGEM.NET library.

- We have been working with SECS/GEM continuously since 2015, always referencing the SEMI specifications. There are almost 200 specifications, spanning over 5,000 pages, each costing between $150 and $350.

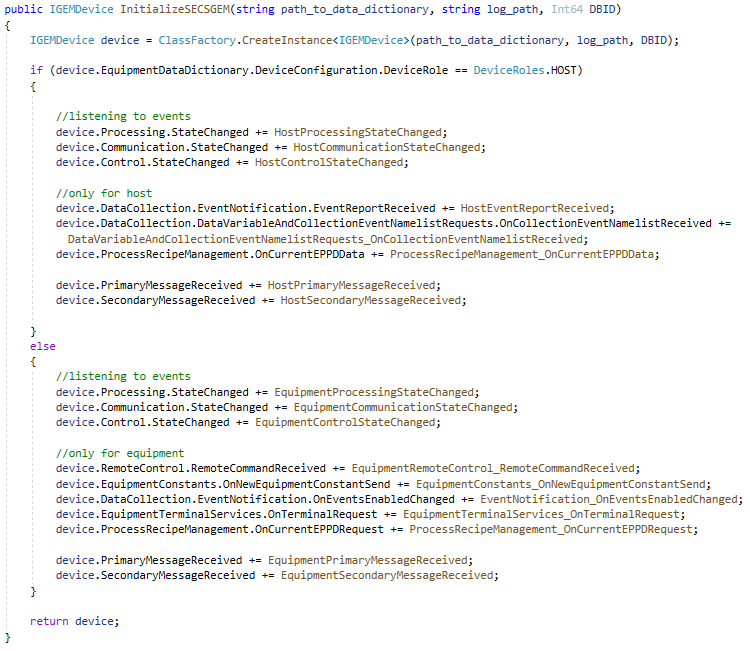

- Our SECS/GEM software, specifically designed for .NET, is incredibly user-friendly. With SECSGEM.NET, most tasks require only one line of code. Sending any message between the host and equipment is just one line. Setting and retrieving variable values, sending custom messages, enabling communication, and accessing data such as collection events, status variables, data variables, equipment constants, and alarms—all take just one line of code.

- Our SECS/GEM Simulator Studio, which is scriptable, allows you to integrate equipment in weeks instead of months. As a factory owner, you can also provide this tool to equipment manufacturers to test their machines against your MES system, drastically reducing the implementation and testing time.

- We offer SECS/GEM online training for beginners.

- We provide extensive examples to help reduce your development time.

Summary:

Download

The SECSGEM.NET Standard Software Installer generates a unique fingerprint based on your computer’s configuration, which will be used to install the SECSGEM.NET Standard Software.

To get started, download and run the SEMI Standard SECS/GEM software:

SECSGEM.NET Standard Software

Requirements::

If you’re using Windows 7 or higher, you likely already have the necessary components installed. If not, please download and install the following prerequisites before proceeding with the SECSGEM.NET / GEM300 setup:

If the provided links don’t work, use the alternative links below:

After installation, review the instructions below on how to integrate SECSGEM.NET with your equipment software. You may also consult the README.TXT or the "SECSGEM.NET Introduction and Developer Guide for .NET 4 and .NET 6.pdf" file provided with the installer.

How do I make my equipment SECS/GEM compliant?

Step: 1

Step: 2

Once SECSGEM.NET is successfully installed, you will find the SECSGEM.NET library files (DLL, .so) in the installation folder. Create a Visual Studio WinForms or WPF Project and add the following references to your project:

- 'SECSGEMInterfaces_NET*.dll'

- 'SECSGEMLicenseNET*_x64.dll'

Step: 3

Refer to the SampleSECSGEMApp folder to see example implementations of Remote Commands, Data Collection Events, and Alarms, and integrate these into your equipment software. If you're not successful, fill out the contact form below, and we will assist you within 24 hours.

Purchase SECS/GEM.NET Software

You can purchase the SECS/GEM Equipment Integration Software through the following options:

- Existing Users: Simply send us your purchase order (PO) directly to acquire SECS/GEM Software.

- New Customers: Please use the contact form below to initiate your first interaction. After your initial purchase, we will guide you through the entire process and provide instructions on how to use SECS/GEM Software. All purchases are governed by our License Agreement. As per the agreement, you are strictly prohibited from disclosing the software to any third party or granting access to it, except in accordance with the agreement.

- Download and run the SECSGEM.NET Installer from our website.

- Enter your business email to receive a download link and product key.

- Complete a wire transfer for the purchase amount to our bank account.

- You will receive SECSGEM.NET and your product key via email.

- Test SECSGEM.NET and integrate it with your software! A sample application is provided for both HOST and EQUIPMENT integration.

15 REASONS to BUY SECSGEM.NET EQUIPMENT CONTROL SOFTWARE:

- Outstanding Support: We provide top-tier support until your integration is successful.

- No High Entry Costs: Unlike competitors who charge $30,000 to $40,000 just for the first license, we keep costs low.

- No Vendor Lock-In: Our API is flexible and does not rely on tight inheritance-based coupling.

- No Dongles: Forget about dongles—you don't need them!

- Cost-Effective: You only pay for the license and features you need.

- SECSGEM.NET/GEM300 is Flexible: It's user-friendly, battle-tested, and constantly improving.

- Supports Both Host and Equipment Roles: Other vendors charge extra for host-side software, but we offer both at an affordable rate.

- Per-Connection Licensing: Licenses are issued per connection and can be transferred.

- C# Source Code Available: Available under agreement, but intellectual property rights remain with us.

- Online Training Available: We offer SECS/GEM & GEM300 training courses online. Contact us for availability and pricing.

- Native .NET Library: SECSGEM.NET/GEM300 is a .NET library, not a wrapper around Java, eliminating the need for additional Java runtime installations.

- No COM+ Components: Avoid issues with deadlocks and performance due to data marshalling.

- Efficient Coding: SECSGEM.NET/GEM300 allows you to accomplish most tasks with a single line of code. We’ll demonstrate this feature in a meeting!

- E142 XML-Based Substrate Map Support: SECSGEM.NET/GEM300 includes support for the E142 standard.

- GEM300 Support: Fully compliant with GEM300.

Note: We provide 64-bit versions by default. For 32-bit versions, please contact us.

Contact

SECSGEM.NET Local Time in Germany:

Your Local Time: